THE RAW TRUTH OF RAW MATERIALS

“Bioneering” new alternatives

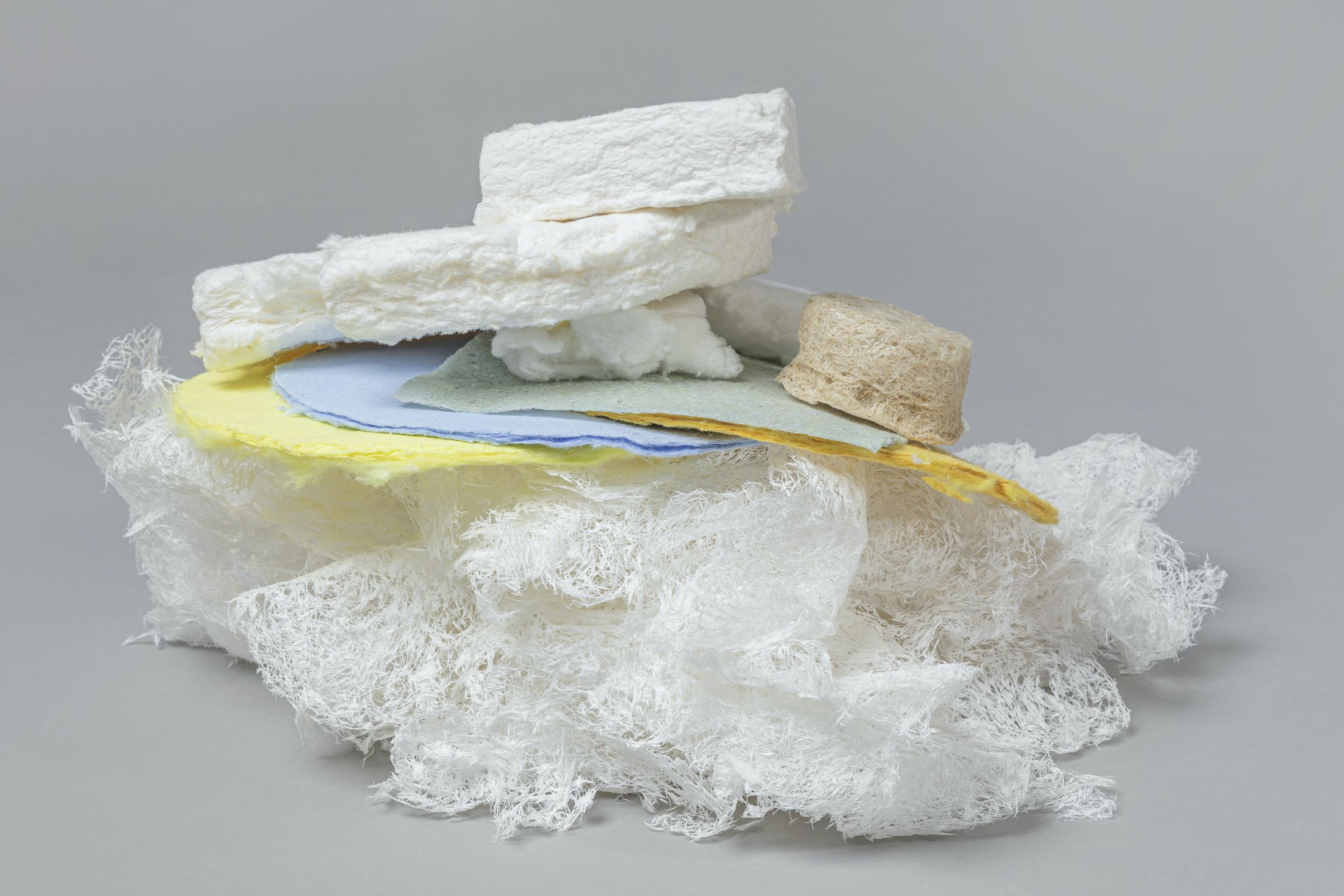

Pulp and biofoam experiments by CHEMARTS, the long-term strategic collaboration between two Aalto University schools. CHEMARTS is run by professors Tapani Vuorinen and Pirjo Kääriäinen. Photos by Eeva Suorlahti.

Pulp and biofoam experiments by CHEMARTS, the long-term strategic collaboration between two Aalto University schools. CHEMARTS is run by professors Tapani Vuorinen and Pirjo Kääriäinen. Photos by Eeva Suorlahti.

We live in a material world, and this means that our need for fashion, clothing and textiles will not be disappearing any time soon. Our clothes will keep on covering, comforting and delighting us.

Having said that, we must acknowledge that when we wear clothes, we’re most likely wearing sustainability problems. Both synthetic, petroleum-based fibres as well as natural fibres such as cotton are linked to serious environmental hazards. New solutions are urgently needed to replace existing, harmful materials and processes.

At Aalto, we love “bioneering”, materials research that generates new solutions in harmony with nature.

We’re asking questions like: how can we reduce, reuse and recycle materials that already exist? And: which waste materials and residues could be turned into something useful? We’re also looking into radically new directions for bio-based materials: what is or could become fibre? Could we make fibres from forest resources? Could we grow materials from microbes or funghi? What about spider silk or seaweed, could they be useful?

Nature is spectacular and could provide us with many innovative resources, as long as we are clever enough to make use of them.

IONCELL®

Ioncell fibre is an inspiring and sustainable new material that can be made from wood or from different types of recycled materials, such as cardboard, newspaper or waste textiles. Ioncell technology uses a novel solvent that is classed as an ionic liquid. The manufacturing process does not use any harmful chemicals, nor does it produce any waste.

As a material, Ioncell is soft and easy to dye, it drapes beautifully and has a gorgeous lustre. It has many other excellent properties too: it’s strong (up to 2–3 times stronger than virgin cotton), absorbs moisture and feels wonderfully comfortable against the skin too.

Ioncell has been developed as a joint effort by Aalto University and the University of Helsinki.

Aalto University student Elina Onkinen and alumna Kasia Gorniak designed this experimental collection from Ioncell yarn and old hand towels and workwear from the textile service company Lindström. The hand towels were recycled into new fibres and yarn using Ioncell technology. 'One wouldn’t realise these garments are made from old hand towels because the material has such a different feel to it’, the designers say. These prototypes show how the life of textiles can be extended by clever design and upcycling.

Photos: Diana Luganski

FLAUX: THE “FLORAL LEATHER”

Roses are red and violets are blue, but the floral industry is massively wasteful unfortunately. Forty per cent of flowers grown for cutting are discarded at some point in the supply chain, never making their way onto dinner tables or first dates.

Aalto University design student Irene Purasachit wanted to find a way to make use of the discarded blooms. As part of her biomaterial work, she dries, grinds and mixes petals into a mass, which is then pressed into a flexible material reminiscent of leather. This experimental material has the potential to be used in lifestyle products as a substitute for animal leather.

The unwanted stems and leaves can also be boiled into a cellulose mixture. After adding a binding agent, this mixture can be either pressed onto a paper or baked into a floral foam. Of the flowers tested to date, irises, carnations, sunflowers and roses, Irene Purasachit’s personal favourites, have proven to work best as a raw material.

The lavish use of flowers is part of everyday life in Irene’s home country Thailand. In her Master’s thesis she has conceptualized flower workshops that combine raw materials, material production, design, and sales into a whole value chain, creating new, sustainable jobs locally. The first workshop is already being planned for Bangkok’s flower market.

Irene Purasachit has also entered negotiations with a small, specialist shoe manufacturer based in Germany. Who knows, we might all be wearing sneakers made of flowers soon?

Flaux was created at CHEMARTS Summer School 2020, with help from professors Tapani Vuorinen and Pirjo Kääriäinen — who run the CHEMARTS study programme.

Photos: Irene Purasachit

CHEMARTS

is a platform for design and materials science students and researchers to develop new bio-based materials together. It organises courses and a Summer School, and it has published The CHEMARTS Cookbook, offering both simple and more advanced recipes for hands-on experimenting. Get inspired and test the recipes!

Read more here.