RADICAL TRANSPARENCY

Supply and value chains have not been designed to be transparent, but the pressure is on to change that.

The textiles, clothing and fashion industry is powerfully driven by cost-efficiency, with many brands focused on seeking out the cheapest solutions. This has led to the manufacturing process becoming highly fragmented. Fabric is now woven in one place, dyed in another, sewn in a third and sold in a fourth location, giving rise to serious concerns about the industry’s involvement in waste production, emissions, poor pay and forced labour.

Today, the pressure is on: consumers increasingly want to know more about where and how the products they purchase are being made. They are actively rewarding companies that build transparency into their supply chains and punishing companies that do not. Meanwhile, NGOs and activists are leaning on brands to be more transparent, investors are getting picky and the regulatory environment is becoming more rigorous. Companies have to take greater responsibility for what is happening in their supply chains and be willing to share their knowledge with consumers.

But the lack of reliable information remains a major problem. Even with the best will in the world, fashion brands find it difficult to know enough about the origin of their raw materials, the details of manufacturing sites and the chemicals used in the manufacturing processes. So, how might they navigate these complex supply chain networks?

Photos: Shutterstock

The Finnish sustainable textile systems research consortium FINIX is pushing for greater transparency within the industry in a number of different ways.

TEXTILE TRACKING

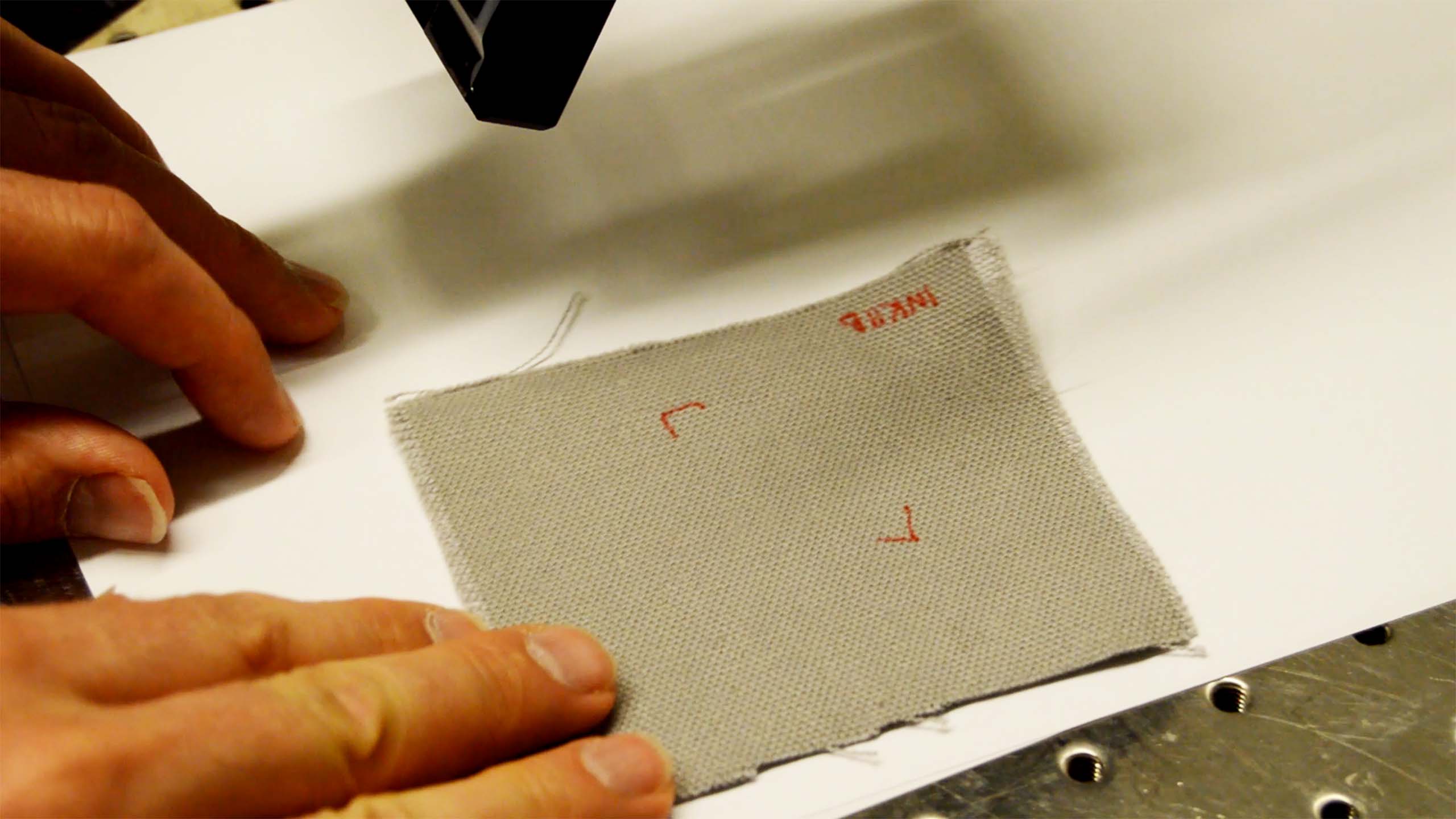

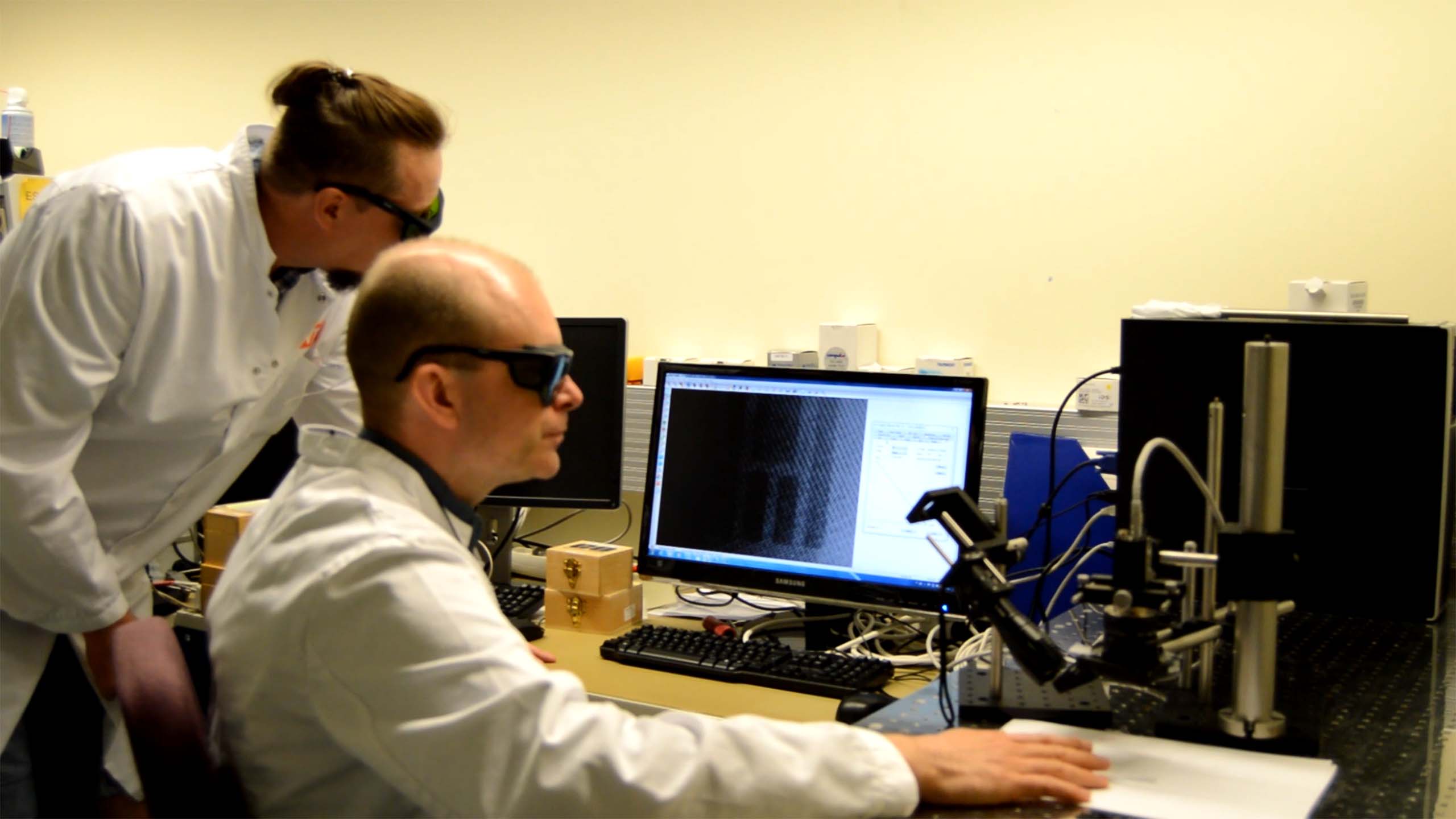

Aalto University and VTT Technical Research Centre of Finland are jointly developing different ways to create unique identifiers for textile products. One prototype is a digital tag that is invisible to the naked eye but can be read with ultraviolet light or hyperspectral imaging. It can be inserted into fibre, yarn or textiles, giving access to the tracing data of each batch of clothing or each individual garment even.

The digital tag could be used to track the origins of the materials and components used, as well as the different chemical processes and manufacturing stages. Once this information can be gathered in one place, it's easier to calculate the overall environmental impacts of a product and, as a next step, to promote more sustainable production practices.

The digital tag can of course carry whatever information is uploaded onto it, giving room for a lot of creativity. So, looking further into the future, could we create a deposit refund system for the recycling of clothes — in a similar way we recycle bottles in the Nordics? Or, could garment producers receive royalties from the resale or rental of their items, encouraging them to produce quality items with a long lifespan?

Perhaps we, as wearers of garments, have a special role in the future, too. Could we start archiving information into our clothes? If our clothes are to have a long life and be passed on to new users, maybe we could celebrate our best-loved pieces by sharing the story of how we came to be so attached to them?

The VTT setup in which the invisible tag can be read with ultraviolet light. Images are screen captures from FINIX video

The VTT setup in which the invisible tag can be read with ultraviolet light. Images are screen captures from FINIX video

LIFECYCLE INFORMATION MANAGEMENT

Aalto University and LAB University of Applied Sciences are creating a digital tool to better equip fashion brands with supply chain tracing capabilities and help them implement track-and-trace for their products.

The current reality is that information about upstream supply chain practices often goes uncollected or is inaccurate. To tackle this problem, the research project encourages companies to share as much accurate information as possible. Companies can use a digital tool to upload images and data on manufacturing sites, chemical processes, the origin of materials and sustainability certification.

Once the volume of data grows and users have agreed on a set of data sharing principles, companies can learn from each other’s practices and enhance their understanding of how to improve the transparency of their own operations.

In the past, businesses and suppliers have feared that, by revealing too much information, they could undermine their competitive advantage or expose themselves to criticism. However, that mindset is now changing. Given the increasing vocal demands for greater transparency, companies are looking for effective, standardised ways to gain visibility into their own supply chains. This work is being driven by a sense of urgency in its own right, but it can also lead to new business models and market opportunities.

Photos: Shutterstock