CHEMARTS

Inspiration for Material Enthusiasts

In the coming years, our material world will change dramatically. In parallel with climate change, our lifestyles will also change. The overuse of existing raw materials cannot continue and global consumption must decrease.

However, our need for materials will not disappear: in the future too, they will come to nurture us, cover us, comfort us, delight us, and keep us alive. This means we need many new ideas, collaboration across all borders and hard work to replace our existing material systems and consumption habits with more sustainable ones. In many cases, bio-based materials are considered the best alternative to currently dominant fossil-based ones. To facilitate this change, we should be curious about what products are made of and about the origin of materials. Knowledge and transparency is urgently needed in all phases of production processes.

The good news is that the new era has already begun: awareness of ecological issues is increasing, recycling is becoming part of our everyday routines, and materials now play a role in several United Nations Sustainable Development Goals. Renewable raw material sources and unused side streams or waste are being researched around the globe. More and more designers and other creative minds are becoming engaged in innovative material research and development processes, together with scientists and engineers. We – the CHEMARTS team – are part of this movement.

CHEMARTS is the long-term collaboration project of two Aalto University schools: the School of Chemical Engineering (CHEM) and the School of Arts, Design and Architecture (ARTS). These schools combined forces in 2011 with the aim of researching bio-based materials in an innovative way and creating new concepts for their advanced use. The core values of CHEMARTS are the sustainable use of natural resources, experimental working methods, and the respectful cross-pollination of design and material research.

CHEMARTS arranges multidisciplinary study courses and a Summer School for degree students, thesis projects, and workshops for elementary and high school students. It also participates in externally funded research projects.

We ask questions such as: Could the innovative use of renewable cellulosic materials change our material world? What kinds of materials can we derive from trees, while still respecting the preciousness of nature? We want to share our experiences by focusing on the topic we know best: materials from the forest. That’s why we’ve created The CHEMARTS Cookbook.

Bio-degradable face masks by Noor Agourram, CHEMARTS Summer School 2020.

Bio-degradable face masks by Noor Agourram, CHEMARTS Summer School 2020.

Flower leather by Bingdie Huang and Irene Purasachit, CHEMSARTS Summer School 2020.

Flower leather by Bingdie Huang and Irene Purasachit, CHEMSARTS Summer School 2020.

The CHEMARTS Cookbook

The CHEMARTS Cookbook is a book about wood- and plant-based materials, especially cellulose, aiming to inspire future professionals to explore the potential. The book showcases experimental results, focusing on raw materials that are processed either chemically or mechanically from trees or other plants: cellulose fibres, micro- or nano- structured fibrils, cellulose derivatives, lignin, bark, and wood extractives. It offers both simple and more advanced ideas and recipes for hands-on experiments with these materials.

The recipes were developed and tested by students and staff in 2014–2019 in the CHEMARTS Laboratory at Aalto. The results are far from commercial applications; hopefully future professionals will get inspired to take some ideas further.

Find inspiration, test our recipes in workshops or laboratories, and develop your own experiments! Have fun!

Photo: Recipe 17: Wooden Transparency.

Recipe 4: Common Reed Panels, Paivi Lehtinen.

Recipe 4: Common Reed Panels, Paivi Lehtinen.

Recipe 2: Pine Bark Reinvented, Aarni Tujula.

Recipe 2: Pine Bark Reinvented, Aarni Tujula.

Recipe 20: Patterning Cellulose, Iines Jakolev.

Recipe 20: Patterning Cellulose, Iines Jakolev.

CHEMARTS Cookbook Foam experiments, Aalto University.

CHEMARTS Cookbook Foam experiments, Aalto University.

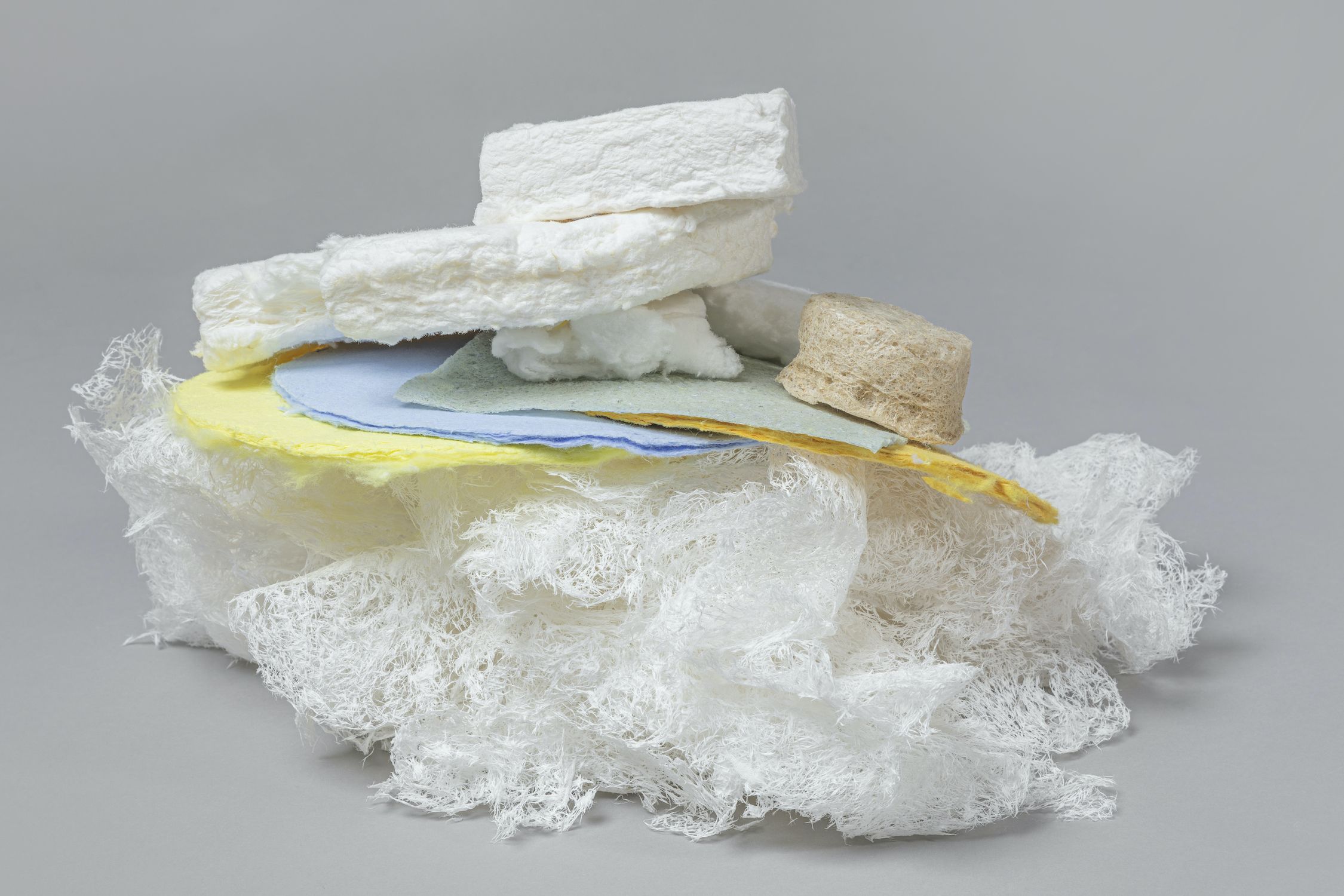

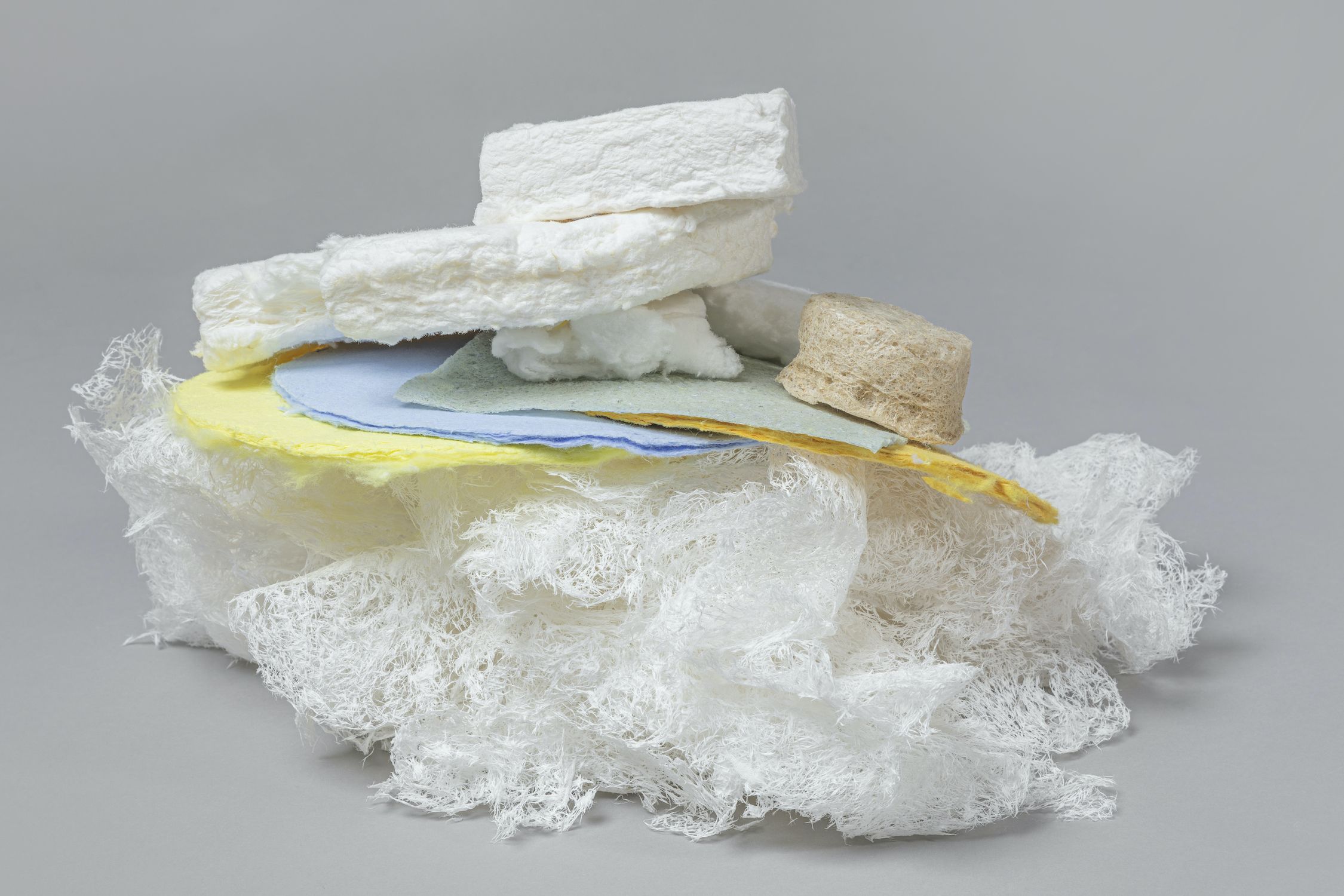

Samples of foamed methyl cellulose (MC) and pulp by Luisa Jannuzzi.

Samples of foamed methyl cellulose (MC) and pulp by Luisa Jannuzzi.

Recipe 9: Pulp Foams.

Recipe 9: Pulp Foams.

Print and digital version of the book available at Aalto ARTS Books.